Concrete trapezoid made of galvanized or painted galvanized hot dip sheet.

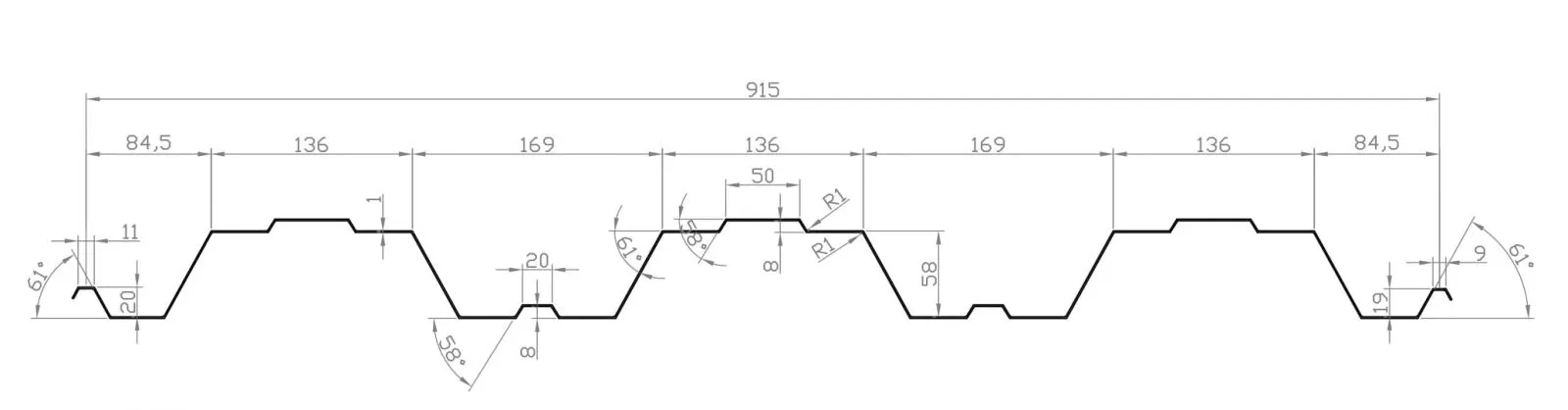

It represents forming galvanized and painted galvanized sheet roll at 58/915 section. It is made in the form of 3-top from 1200 mm wide roll.

UMS 58/195 concrete trapezoid is designed for use in composite floorings. These materials serve as a platform for the workers and materials during the course of construction, and as a mold for wet cast concrete. Afterwards, when the concrete is set and gains sufficient strength, and adherence to the concrete is ensured, they help composite work by meeting all or part of tensile component in the flooring.

Trapezoidal plate behaves differently during mold period and composite process. During the mold period, trapezoidal sheet is exposed to bending and shearing effects because of the loads on it. During composite process, trapezoidal sheet generally forms the tensile component of composite section, depending on the location of neutral axis. However, even if rarely, in some adverse situations it provides resistance to pressure and tensile together with concrete.

These two behaviour patterns mentioned above are analyzed separately and related calculation tables are formed accordingly. Eurocode 4 “Design of Composite Steel and Concrete Structures” of European Union standards is taken as a principal reference in calculations. It is accepted that shear between concrete and steel in the behavior during the composite process is prevented. It is also considered that in the composite work all shear force formed in the section is met by concrete component.

| Hot Dip Galvanized 58/915 Concrete Trapezoid Technical Specifications: | |

| Thickness | 0,70 – 1,50 mm |

| Width | 915 mm |

| Length | 100 – 13000 mm |

| Coating Thickness (total of two surfaces) | 50 – 350 gr/m2 |

| Steel Type | Steel Type: Steels Suitable for Cold Forming (DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z) Non-Alloy Structural Steels (S220 GD+Z, S250 GD+Z, S280 GD+Z, S320 GD+Z, S350 GD+Z) |

| Hot Dip Painted 58/915 Concrete Trapezoid Technical Specifications: | |

| Thickness | 0,70 – 1,50 mm |

| Width | 915 mm |

| Length | 100 – 13000 mm |

| Coating Thickness (total of two surfaces) | 50 – 350 gr/m2 |

| Steel Type | Steel Type: Steels Suitable for Cold Forming (DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z) Non-Alloy Structural Steels (S220 GD+Z, S250 GD+Z, S280 GD+Z, S320 GD+Z, S350 GD+Z) |

| Paint Type | Polyester, Pvdf, Plastisol, PVC |

| Color Options | Can be produced in all RAL codes. |

| UMS 58/915 Section Specifications: | ||||||

| Wall Thickness: (mm) | 0.70 | 0.80 | 0.90 | 1.00 | 1.20 | 1.50 |

| Area A: (mm2) | 840 | 960 | 1080 | 1200 | 1440 | 1800 |

| Unit Weight G: (kg/m2) | 7.21 | 8.24 | 9.27 | 10.3 | 12.4 | 15.4 |

| Moment of Inertia i: (mm2) | 551177 | 629869 | 708560 | 787244 | 944594 | 1180587 |

| Principal Axis Distance c: (mm2) | 33.48 | 33.52 | 33.56 | 33.60 | 33.68 | 33.80 |

| Moment of Resistance W: (mm2) | 16462.69 | 18790.84 | 18790.84 | 23429.88 | 28046.14 | 34928.61 |

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C Profili: | ||||

| Tavan U Profili: | ||||

| Agraf: | ||||

| Klips: | ||||

| Ekleme Parçası: | ||||

| Derz Bandı: | ||||

| Borozan Vida | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C Profili: | ||||

| Tavan U Profili: | ||||

| Askı Maşası: | ||||

| Askı Çubuğu: | ||||

| Klips: | ||||

| Ekleme Parçası: | ||||

| Derz Bandı: | ||||

| Borozan Vida | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| Malzeme Adı | Tek Dikmeli Tek Katlı Kaplama | Tek Dikmeli Çift Katlı Kaplama | Tek Dikmeli Üç Katlı Kaplama | |||

| TEK C | ÇİFT C | TEK C | ÇİFT C | TEK C | ÇİFT C | |

| Alçı Levha | ||||||

| Duvar C Profili | ||||||

| Duvar U Profili | ||||||

| Delikli Köşe Profili | Tam Yüksekliği x Köşe Sayısı | |||||

| Dez Bandı | ||||||

| Derz Alçısı | ||||||

| Borazan Vida (25 mm) | ||||||

| Borazan Vida (35 mm) | ||||||

| Borazan Vida (45 mm) | ||||||

| Dübel-Pul-Vida | ||||||

| Yalıtım Malzemesi | 1.00 m² | |||||

| Malzeme Cinsi | Aks Aralığı | ||||||

| Çimentolu Levha veya Alçı Levha | |||||||

| CT Profili | |||||||

| L Braket | |||||||

| Çelik Dübel | |||||||

| Matkap Uçlu Vida | |||||||

| Borozan Vida | |||||||

| Malzeme Cinsi | Aks Aralığı | ||||||

| 600 mm | 400 mm | ||||||

| Çimentolu Levha veya Alçı Levha | |||||||

| M Profili | |||||||

| J Profili | |||||||

| L Braket | |||||||

| Çelik Dübel | |||||||

| Trapez Vida | |||||||

| Brozan Vida | |||||||

| Malzeme Çinsi | Tek Katlı Alçı Levha (Aks Aralığı mm) | Çift Katlı Alçı Levha (Aks Aralığı mm) | |||||||

| Alçı Levha | |||||||||

| Tavan U Profili | |||||||||

| Tavan C Profili | |||||||||

| Ses Yalıtım Bandı | |||||||||

| Dübel-Vida | |||||||||

| Agraf | |||||||||

| Agraf Vidası | |||||||||

| Borozan Vida 25 | |||||||||

| Borozan Vida 28 | |||||||||

| Derz Bandı | |||||||||

| Delikli Köşe Profili | (kat y�ksekli?i) x (k�?e say?s?)'na g�re | ||||||||

| Malzeme Çinsi | Tek Katlı Alçı Levha (Aks Aralığı mm) | Çift Katlı Alçı Levha (Aks Aralığı mm) | |||||||

| Alçı Levha | |||||||||

| Duvar U Profili | |||||||||

| Duvar C Profili | |||||||||

| Ses Yalıtım Bandı | |||||||||

| Dübel-Vida | |||||||||

| Borozan Vida 25 | |||||||||

| Borozan Vida 28 | |||||||||

| Derz Bandı | |||||||||

| Delikli Köşe Profili | (kat yüksekliği) x (köşe sayısı)'na göre | ||||||||

| TANIM | SARFIYATI | |||

| Alçı Levha: | ||||

| Omega U Profili: | ||||

| Omega Profili: | ||||

| Tavan U Profili: | ||||

| Çengelli Askı Teli: | ||||

| Askı Çubuğu: | ||||

| Askı Klipsi: | ||||

| Çiftli Yay: | ||||

| Derz Bandı: | ||||

| Borozan Vida: | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C47 Profili: | ||||

| Tırnaklı L Profili: | ||||

| Vidalı Tel: | ||||

| Askı Çubuğu: | ||||

| Özel Klips: | ||||

| Çiftli Yay: | ||||

| Ekleme Parçası | ||||

| Derz Bandı: | ||||

| Borozan Vida: | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C Profili: | ||||

| Tavan U Profili: | ||||

| Agraf: | ||||

| Klips: | ||||

| Ekleme Parçası: | ||||

| Derz Bandı: | ||||

| Borozan Vida | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın Teknik Detayına Göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C Profili: | ||||

| Tavan U Profili: | ||||

| Askı Maşası: | ||||

| Askı Çubuğu: | ||||

| Klips: | ||||

| Ekleme Parçası: | ||||

| Derz Bandı: | ||||

| Borozan Vida | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| Malzeme Adı | Tek Dikmeli Tek Katlı Kaplama | Tek Dikmeli Çift Katlı Kaplama | Tek Dikmeli Üç Katlı Kaplama | |||

| TEK C | ÇİFT C | TEK C | ÇİFT C | TEK C | ÇİFT C | |

| Alçı Levha | ||||||

| Duvar C Profili | ||||||

| Duvar U Profili | ||||||

| Delikli Köşe Profili | Tam Yüksekliği x Köşe Sayısı | |||||

| Dez Bandı | ||||||

| Derz Alçısı | ||||||

| Borazan Vida (25 mm) | ||||||

| Borazan Vida (35 mm) | ||||||

| Borazan Vida (45 mm) | ||||||

| Dübel-Pul-Vida | ||||||

| Yalıtım Malzemesi | 1.00 | |||||

| Malzeme Cinsi | Aks Aralığı | ||||||

| Çimentolu Levha veya Alçı Levha | |||||||

| CT Profili | |||||||

| L Braket | |||||||

| Çelik Dübel | |||||||

| Matkap Uçlu Vida | |||||||

| Brozan Vida 25 | |||||||

| Malzeme Cinsi | Aks Aralığı | ||||||

| Çimentolu Levha veya Alçı Levha | |||||||

| M Profili | |||||||

| J Profili | |||||||

| L Braket | |||||||

| Çelik Dübel | |||||||

| Trapez Vida | |||||||

| Brozan Vida | |||||||

| Malzeme Çinsi | Tek Katlı Alçı Levha (Aks Aralığı mm) | Çift Katlı Alçı Levha (Aks Aralığı mm) | |||||||

| Alçı Levha | |||||||||

| Tavan U Profili | |||||||||

| Tavan C Profili | |||||||||

| Ses Yalıtım Bandı | |||||||||

| Dübel-Vida | |||||||||

| Agraf | |||||||||

| Agraf Vidası | |||||||||

| Borozan Vida 25 | |||||||||

| Borozan Vida 28 | |||||||||

| Derz Bandı | |||||||||

| Delikli Köşe Profili | (kat yüksekliği) x (köşe sayısı)'na göre | ||||||||

| Malzeme Çinsi | Tek Katlı Alçı Levha (Aks Aralığı mm) | Çift Katlı Alçı Levha (Aks Aralığı mm) | |||||||

| Alçı Levha | |||||||||

| Duvar U Profili | |||||||||

| Duvar C Profili | |||||||||

| Ses Yalıtım Bandı | |||||||||

| Dübel-Vida | |||||||||

| Borozan Vida 25 | |||||||||

| Borozan Vida 28 | |||||||||

| Derz Bandı | |||||||||

| Delikli Köşe Profili | (kat yüksekliği) x (köşe sayısı)'na göre | ||||||||

| TANIM | SARFIYATI | |||

| Alçı Levha: | ||||

| Omega U Profili: | ||||

| Omega Profili: | ||||

| Tavan U Profili: | ||||

| Çengelli Askı Teli: | ||||

| Askı Çubuğu: | ||||

| Askı Klipsi: | ||||

| Çiftli Yay: | ||||

| Derz Bandı: | ||||

| Borozan Vida: | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C47 Profili: | ||||

| Tırnaklı L Profili: | ||||

| Vidalı Tel: | ||||

| Askı Çubuğu: | ||||

| Özel Klips: | ||||

| Çiftli Yay: | ||||

| Ekleme Parçası | ||||

| Derz Bandı: | ||||

| Borozan Vida: | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C Profili: | ||||

| Tavan U Profili: | ||||

| Agraf: | ||||

| Klips: | ||||

| Ekleme Parçası: | ||||

| Derz Bandı: | ||||

| Borozan Vida | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın Teknik Detayına Göre | |||

| TANIM | m² SARFIYATI | ||||

| Alçı Levha: | |||||

| Tavan C Profili: | |||||

| Tavan U Profili: | |||||

| Askı Maşası: | |||||

| Askı Çubuğu: | |||||

| Klips: | |||||

| Ekleme Parçası: | |||||

| Derz Bandı: | |||||

| Borozan Vida | |||||

| Çelik Dübel: | |||||

| Plastik Dübel,Pul,Vida: | |||||

| Derz Dolgu Alçısı: | |||||

| Saten Perdah Alçısı: | |||||

| Yalıtım Bandı: | |||||

| Yalıtım Malzemesi (İsteğe Bağlı): | |||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | ||||

| Malzeme Adı | Tek Dikmeli Tek Katlı Kaplama | Tek Dikmeli Çift Katlı Kaplama | Tek Dikmeli Üç Katlı Kaplama | |||

| TEK C | ÇİFT C | TEK C | ÇİFT C | TEK C | ÇİFT C | |

| Alçı Levha | ||||||

| Duvar C Profili | ||||||

| Duvar U Profili | ||||||

| Delikli Köşe Profili | Tam Yüksekliği x Köşe Sayısı | |||||

| Dez Bandı | ||||||

| Derz Alçısı | ||||||

| Borazan Vida (25 mm) | ||||||

| Borazan Vida (35 mm) | ||||||

| Borazan Vida (45 mm) | ||||||

| Dübel-Pul-Vida | ||||||

| Yalıtım Malzemesi | 1.00 | |||||

| Malzeme Cinsi | Aks Aralığı | ||||||

| Çimentolu Levha veya Alçı Levha | |||||||

| CT Profili | |||||||

| L Braket | |||||||

| Çelik Dübel | |||||||

| Matkap Uçlu Vida | |||||||

| Brozan Vida 25 | |||||||

| Malzeme Cinsi | Aks Aralığı | ||||||

| Çimentolu Levha veya Alçı Levha | |||||||

| M Profili | |||||||

| J Profili | |||||||

| L Braket | |||||||

| Çelik Dübel | |||||||

| Trapez Vida | |||||||

| Brozan Vida | |||||||

| Malzeme Çinsi | Tek Katlı Alçı Levha (Aks Aralığı mm) | Çift Katlı Alçı Levha (Aks Aralığı mm) | |||||||

| Alçı Levha | |||||||||

| Tavan U Profili | |||||||||

| Tavan C Profili | |||||||||

| Ses Yalıtım Bandı | |||||||||

| Dübel-Vida | |||||||||

| Agraf | |||||||||

| Agraf Vidası | |||||||||

| Borozan Vida 25 | |||||||||

| Borozan Vida 28 | |||||||||

| Derz Bandı | |||||||||

| Delikli Köşe Profili | (kat yüksekliği) x (köşe sayısı)'na göre | ||||||||

| Malzeme Çinsi | Tek Katlı Alçı Levha (Aks Aralığı mm) | Çift Katlı Alçı Levha (Aks Aralığı mm) | |||||||

| Alçı Levha | |||||||||

| Duvar U Profili | |||||||||

| Duvar C Profili | |||||||||

| Ses Yalıtım Bandı | |||||||||

| Dübel-Vida | |||||||||

| Borozan Vida 25 | |||||||||

| Borozan Vida 28 | |||||||||

| Derz Bandı | |||||||||

| Delikli Köşe Profili | (kat yüksekliği) x (köşe sayısı)'na göre | ||||||||

| TANIM | SARFIYATI | |||

| Alçı Levha: | ||||

| Omega U Profili: | ||||

| Omega Profili: | ||||

| Tavan U Profili: | ||||

| Çengelli Askı Teli: | ||||

| Askı Çubuğu: | ||||

| Askı Klipsi: | ||||

| Çiftli Yay: | ||||

| Derz Bandı: | ||||

| Borozan Vida: | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||

| TANIM | m² SARFIYATI | |||

| Alçı Levha: | ||||

| Tavan C47 Profili: | ||||

| Tırnaklı L Profili: | ||||

| Vidalı Tel: | ||||

| Askı Çubuğu: | ||||

| Özel Klips: | ||||

| Çiftli Yay: | ||||

| Ekleme Parçası | ||||

| Derz Bandı: | ||||

| Borozan Vidalar: | ||||

| Çelik Dübel: | ||||

| Plastik Dübel,Pul,Vida: | ||||

| Derz Dolgu Alçısı: | ||||

| Saten Perdah Alçısı: | ||||

| Yalıtım Bandı: | ||||

| Yalıtım Malzemesi (İsteğe Bağlı): | ||||

| Köşe Profili (Köşe Bandı): | Tavanın teknik detayına göre | |||